ENGINEERING SINCE 1957

MATERIALS

We have a LOT of materials available. We can supply you with low-cost basic expanded plastics such as expanded polystyrene (EPS) all the way through very exotic high performance blends. Which material is right for you depends on:

- The functional needs of your project/product.

- The logistics chain your products move through.

- The material handing needs of your process.

- The budgetary boundaries of the program.

- Your aesthetic needs or intended impression on the end-user.

Choosing the right material can be complicated. We have plenty of very experienced sales people and engineers to help you. In fact, a lot of our sales people are engineers.

Materials Overview

There are six primary materials available that fall into two basic categories: styrenic and olefinic. More specialty materials are available and what follows below is a guideline. Please contact your local FFI representative for exact and specific information.

|

Material Trade Name |

Material Full Name/Discription |

Relative Cost – Basic Function |

|

styrene |

|

|

|

EPS |

Expanded Polystyrene |

Low cost basic cushioning/blocking and bracing |

|

Arcel® |

Polystyrene/Polyethylene Co-Polymer |

Medium cost and somewhat resilient (more than EPS) and very durable (tough) |

|

olefins |

|

|

|

EPP |

Expanded Polypropylene |

Higher cost and very resilient – general purpose resilient material |

|

EPE |

Expanded Polyethylene |

Higher cost and very resilient – soft and good shear strength too (very low wt. and high wt. applications) |

The relative costs are only intended to be a helpful predictive index. In fact, the higher cost resins don’t always turn out to be that way. For example, if migrating into a higher cost resin avoids product damage or reduces the overall package size, the net cost of the pack could actually be less than that of a lower cost material. In the end, each product, its fragility and logistics profile dictate material choice. It boils down to a cost/performance trade off.

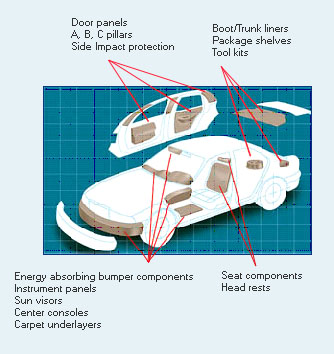

Automotive

Due to its unique physical properties, EPP is used extensively in the automotive industry, as depicted in the diagram here.

This is general information meant to convey broad concepts. Please contact your local FFI representative for specific information.

EPS Regular

EPS is a unique material. You will now see how and why its great physical properties and low-cost make it a global favorite.

What follows is very general information about EPS for illustrative purposes. Please contact your local FFI representative for current and exact information.

When choosing EPS, original equipment manufacturers realize cost savings across the board. Beyond its competitive material pricing, EPS – because of its versatility and lightweight characteristics – can offer savings in design and development, product assembly and distribution costs.

Mechanical Properties

The mechanical properties of molded EPS depend largely on density. Generally, strength characteristics increase with density. However, variables such as the grade of raw material used, geometry of the molded part and processing conditions will affect package properties and performance.

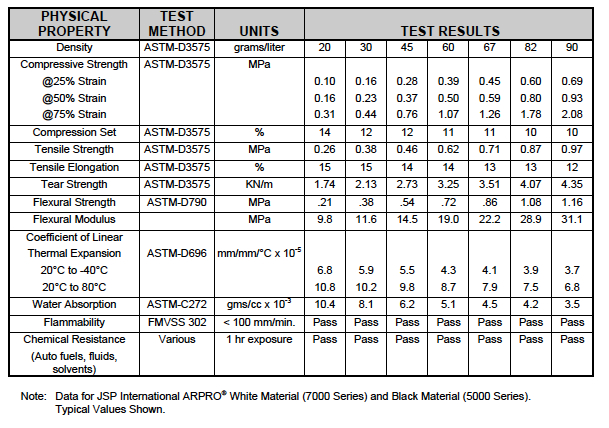

As seen in the table below, most properties of foams are strong functions of density, which allows a processor to fine-tine the exact performance needed by a simple processing change, without redesign of tooling.

|

Density, lb./cu.ft. |

1.0 |

2.0 |

3.0 |

|

Compressive strength |

12 -17 |

31- 37 |

52 – 56 |

|

Tensile strength |

22 – 27 |

58 – 61 |

92 – 95 |

|

Thermal resistance |

3.8 |

4.2 |

4.3 |

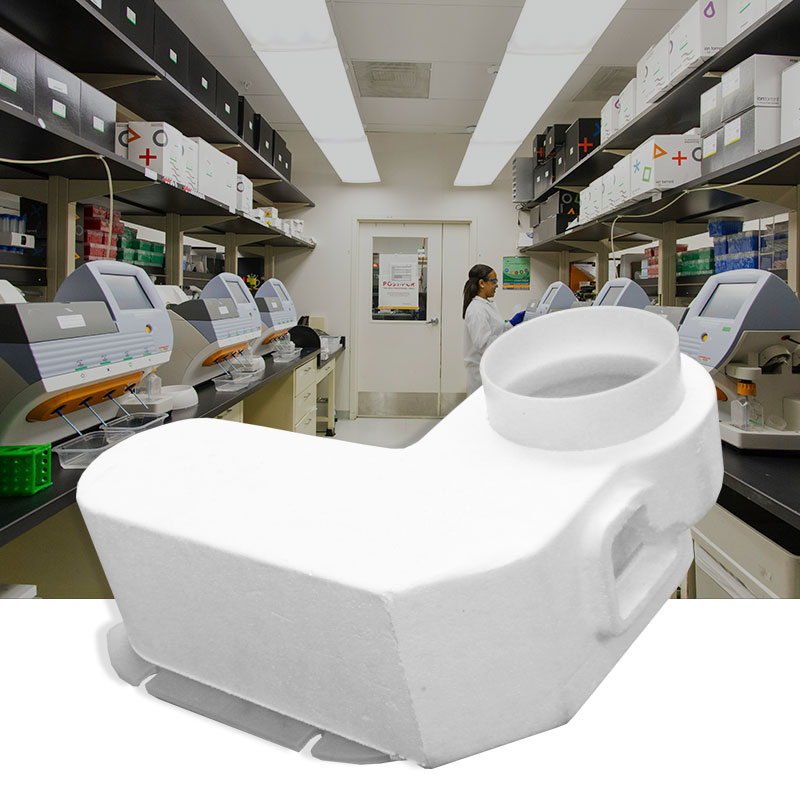

Superior Insulation Value

Many temperature sensitive pharmaceutical and medical products use EPS because comparable packaging materials can rarely offer the same level of thermal insulation. Strongly relied upon in the food distribution industry, EPS is ideal for long distance shipment of perishable foods.

EPS is highly resistant to heat flow. Its uniform, closed cellular structure limits radiant, convective and conductive heat transfer. The thermal conductivity (k factor) of molded polystyrene varies with density and exposure to temperature, as shown in the table below

|

Density, lb/cu.ft |

Temperature (F) |

Btu-in/sq.ft./hr (F) |

|

1.0 |

0 |

.22 |

|

1.0 |

40 |

.24 |

|

1.0 |

75 |

.26 |

|

1.0 |

100 |

.28 |

|

2.0 |

0 |

.20 |

|

2.0 |

40 |

.21 |

|

2.0 |

75 |

.23 |

|

2.0 |

100 |

.25 |

Water absorption and transmission

The cellular structure of molded polystyrene is essentially impermeable to water and provides zero capillary. However, EPS may absorb moisture when it is completely immersed due to its fine interstitial channels within the bead-like structure.

While molded polystyrene is nearly impermeable to liquid water, it is moderately permeable to vapors under pressure differentials. Vapor permeability is a function of both density and thickness. Generally, neither water nor vapor affects the mechanical properties of EPS.

Electrical Properties

The volume resistively of molded polystyrene within the 1.25-2.5 PCF density range, conditioned at 73 F and 50% r.h. is 4×1013 ohm-cm. The dielectric strength is approximately 2KV/mm. At frequencies up to 400 MHz, the permittivity is 1.02-1.04 with a loss factor less than 5×10-4 at 1MHz and less than 3×10-5 at 400 MHz. Molded EPS can be treated with anti-static agents to comply with electronic industry and military packaging specifications.

Chemical Resistance

Water and aqueous solutions of salts, acids and alkalis do not affect molded polystyrene. However, most organic solvents are not compatible with EPS. This should be taken into consideration when selecting adhesives, labels and coatings for direct application to the product. All substances of unknown composition should be tested for compatibility. Accelerated testing may be carried out by exposing molded polystyrene to the substance at 120-140 F.

UV radiation has a slight effect on molded polystyrene. It causes superficial yellowing and friability, but does not otherwise affect physical properties.

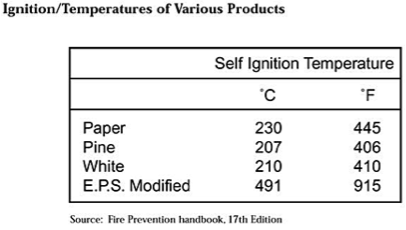

EPS Fire Retardant

“Modified” EPS is the same basic material as “regular” EPS other then the fact that M-EPS is self-extinguishing. This material will only burn in the presence of an ignition source. When the ignition source is removed the EPS self extinguishes.

The requirements of all the major code organizations for “modified” (fire retardant or self extinguishing) EPS is that they have a flame spread of not more than 75 and a smoke development rating of not more than 450. The standard test for this is ASTME84-87.

All of the information above is very general in nature and only meant to illustrate the basic concept. Please contact your local FFI representative for exact and current information pertaining to your specific needs.

ARCEL

ARCEL® is a moldable copolymer (PE and EPS) foam which is resistant to tearing, puncturing, cracking and flaking. Strong and durable, ARCEL offers long-term reusability, and low compressive creep makes it ideal for long-term stacking. ARCEL’s cushioning capabilities absorb shocks without decreasing its protective efficiency, making it an excellent option for extreme conditions, heavyweight items or reusable trays. It is used to cushion and protect objects from small, delicate instruments to large, heavy products.

Hewlett Packard Corporation (HP) specified ARCEL moldable foam resins from NOVA Chemicals Corporation (NOVA Chemicals) for packaging and handling of its Color Laser Jet 8550 DN Printer. ARCEL is an expandable resilient moldable foam resin.

According to HP, the need for packaging that cushions and withstands higher levels of impact is being driven by the increase in Internet business-to-consumer distribution. “With more and more ‘uncontrolled’ overnight shipments from internet orders, we need to be sure that our printers arrive safely and without damage,” said Lou Gregorek, HP Packaging Engineering. “Since using ARCEL resins for our packaging, we’ve had substantially fewer complaints and returns from our customers.”

Lightweight yet strong, packaging made from ARCEL resins offer a cost-effective option for custom molded resilient packaging. Applications for ARCEL resins continue to expand as molders and designers explore the many capabilities of this versatile material. Recent applications include personal computer packaging, infant car seats, automotive dunnage, marine dock bumpers and boogie boards.

ARCEL At-A-Glance

- Comparable in performance to expandable polypropylene (EPP) & expandable polyethylene (EPE)

- Nine times stronger then expandable polystyrene (EPS) at the same density

- Processible on standard expandable polystyrene (EPS) molding equipment

- The only “in-the-tool” solution to an EPS failure

or performance upgrade - Recycled with PS under Society of the Plastics Industry (SPI) code #6

- Available in all world regions

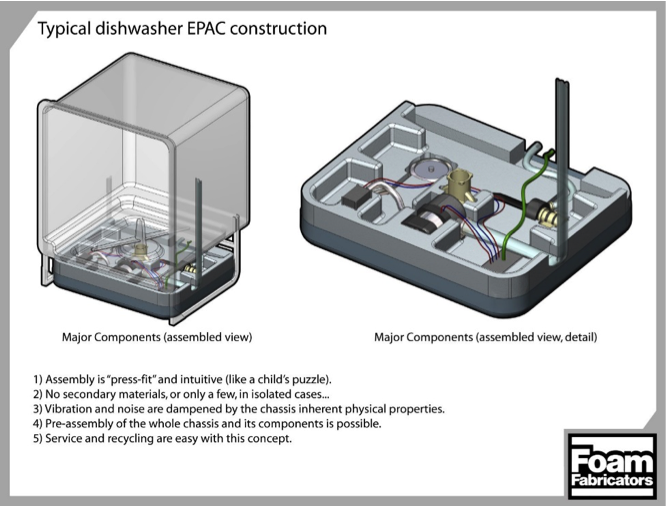

Pourous EPP (P-EPP)

JSP has developed a unique form of EPP, which features air pockets, or voids, within the bead structure. Shaped in cylinder form, as opposed to spherical form, Porous EPP (P-EPP) provides distinct advantages in certain applications, including acoustical panels for use in challenging environments.

The cylinder shape of P- EPP beads lessens the component weight, increases acoustical performance in certain frequency ranges, and results in a very lightweight product with resilience and good structural integrity.

To read more about this unique material follow this link P-EPP tech bulletin.

This is a great material for managing noise and is capable working in and around.

Shock / Vibration

Fire / Heat

Water / Moisture

Documentation Downloads

What might an application be for P-EPP?

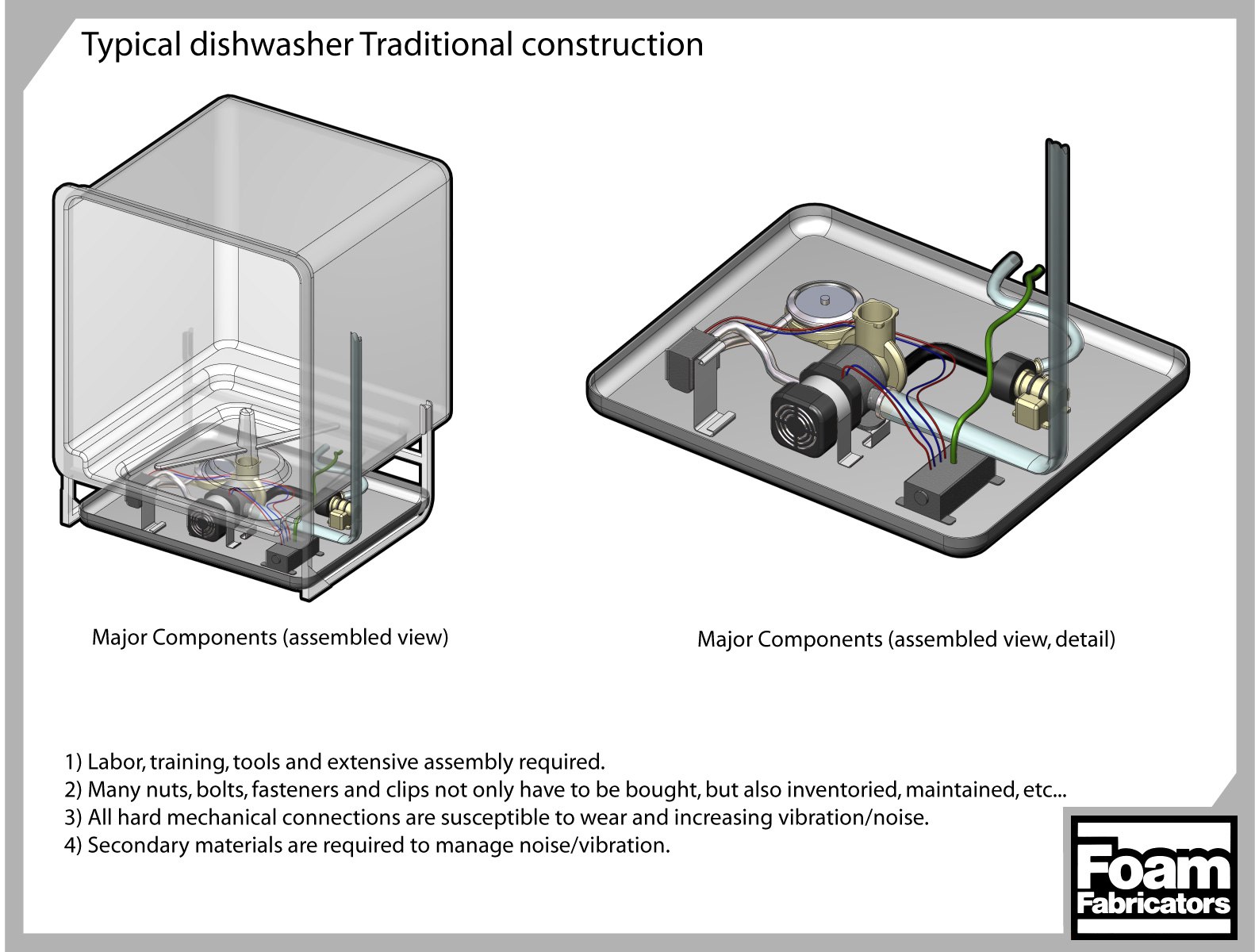

The concept on the left below shows a typical dishwasher with traditional construction. With the concept below on the right the dishwasher would be much quieter and manufacturing would be greatly streamlined!

Airdex Pallets

Foam Fabricators has been molding Airdex pallets for several years… It’s a great product!

New Wood Packaging Export Regulations

Governments around the world are increasingly restricting the use of all forms of wood packaging, including pallets, crates, and skids. These restrictions are intended to stop the introduction of foreign pests and have created an expensive and complex scenario of interpretations of regulations, compliance methods and documentation procedures for exporters. They combine to create new risks to the exporter, ranging from total shipment rejections to expensive (perhaps product damaging) delays in the shipping process.

Here are nine product features that are EXCLUSIVE to AIRDEX. Each of them offers important BENEFITS to Import/Export and Airfreight users.

- A very light weight pallet at only 6-11 lbs depending on coating and strength requirement) typically from 1,500 to 3,000 lbs dynamic load weight. Saves Airfreight weight costs as well as oververall transportation expenses.

- Thermally insulated with high R & K factors to maintain temperature sensitive shipments: food, pharmaceutical, biotech, etc.

- Shock absorbing, with high S-curve coefficient to protect sensitive cargo: food, hi tech, instruments, etc.

- A very safe pallet for Humans, Environment, and Freight because: light weight means no lifting injuries, no sharp edges means no cutting of human skin or product containers, no bugs, rodents, or vermin can live in pallet so it is safe to the environment.

- It’s totally waterproof (in-out of freezers without surface ice or moisture… and it floats!) Directly washable/rinse-able.

- Medically certified and sanitary with EPA/FDA, HACCP full-surface coating of High Impact Polystyrene. Fully “Autoclave” safe.

- It is an RF (radio frequency) invisible pallet. RFID Tags can be implanted internally anywhere inside the pallet core.

- Very tamper proof. Expensive freight cannot be pilfered from underneath as pallet construction will obviate any ingress or tampering.

We look forward from hearing from you. Whether is is a stock item you need quickly or a custom project fulfilled, Altor Soliutions is your solution for everything PIC.