ALTOR Foam Fabrication

Die Cutting | Saw Cutting | Convoluting | Computer Profile Cutting |

Hot Wire Slicing | Custom Machining

FABRICATING FOAM, as opposed to molding, is a great way to get started. Fabricated foams typically cost more than molded foam, but the tooling (or molds) usually cost 1/10th of what custom molded foam tooling does. Typical applications are:

- Medium to low volume projects.

- New products where the item being packaged might change soon (requiring a different pack).

- Programs that just don’t have the budget to support hard tooling right now.

- Testing programs still under development.

- Some companies just like fabricated foams!

We have a number of fabricating options and our engineering team can assist you with

determining the right path, material and process.

Die Cutting

Die Cutting- A process by which foam is cut using steel rule mounted in plywood. The steel rule is bent to the shape of the desired product.

Typical plywoods used are hardwoods such as birch or ash at ½ to 5/8 thicknesses. The steel rule comes in heights of 0.937, 1, 1.125 1.25, and 1.5 inches. This height is measured from the back of the board to the tip of the edge. Typical edges manufactured are center beveled, scallop, serrated, etc….Typical foams cut using this process are PE, PU.

Saw Cutting

Saw Cutting- A process by which foam is cut using a large band saw similar to woodworking. These particular band saws have a blade height above 60” and a throat of 60”. Different blades are used for different types of product. Some of these industrial saws have the ability to cut up to 45 degree angles.

Convoluting

A process by which foam is cut using a series of meshed teeth to compress the foam while cutting. The cutting blade is in the center of the meshed teeth. This process produces an “egg crate” effect on the foam thus resulting in two mirror imaged parts that perfectly fit together. Low density polyurethanes are the only foams that can be used on this equipment.

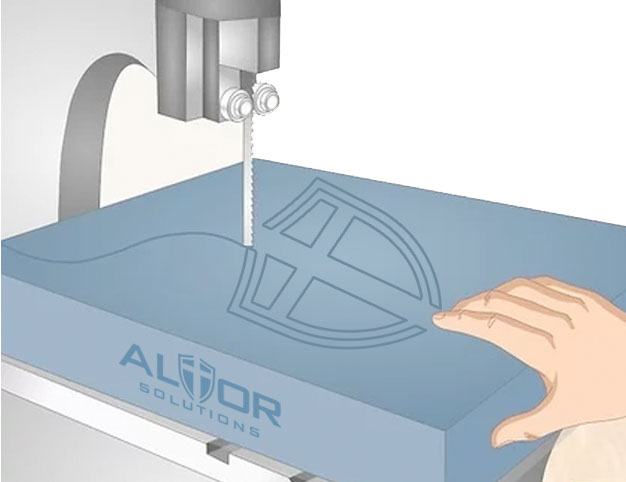

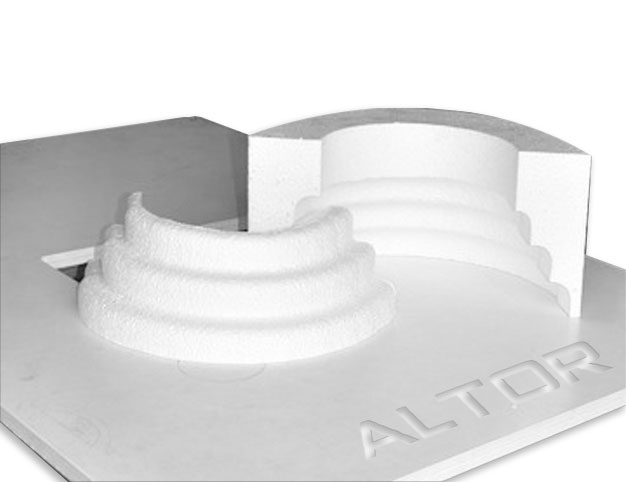

Computer Profile Cutting

A process by which foam is cut using a series of “hot wires.” These wires produce heat by running electrical current through them thus melting away the foam in their path. The computer controls the wires by a series of X, Y, and Z axis stepper motors.

Typical foams cut using this process are polystyrene and polyethylene.

Hot Wire Slicing

Hot/Wire Slicing- A process by which foam is cut using hot wires. Similar to the computer cut, these wires are heated using electrical current. As the computer cutter can produce multiple shapes, the Slicer and or Downcutter can only produce rectangular or square shapes.

Custom Machines

With the customer requirements in mind, we have the ability to customize special jigs and machines to perform specific types of cuts to different types of foams. In many cases if we do not have a piece of equipment to perform these tasks, we can custom design it.