PACKAGE ENGINEERING SINCE 1957

Packaging

FoamFabricators is a solutions-based company!

Packaging: Just what it sounds like. Usually molded foam is on the outside

of an item (EPP computer caps for example), and typically inside an outer

container or carton. In this area you’ll see several subsets of this market

segment.

CELEBRATING 60+ YEARS

OUR PACKAGING SERVICES

Material Selection, Engineering Design, Molded & Fabricated Solutions –All Delivered with over 65 Years of Experience with countless industries and applications. Some highlights:

High Tech

Molded foams are used to protect many high-tech products such as personal computers, servers, printers and lots of peripheral devices. This has been the case since the early 1980’s when molded EPS was sourced for some of the very first mass-produced desktop PC’s. Today molded foam is still the first choice for the largest high-tech manufacturers in the world. It’s clean, light weight, low cost and it works!

Appliances

Both the large appliance (refrigerators, dishwashers, washers/dryers, etc.) and small counter-top appliance (blenders, microwaves and the like) industries have depended on molded foam for decades. Our customers like the custom fit, cushioning performance and its global availability. New concepts such as “clear-view” (shipping appliances with no outer corrugated container) are made possible due to molded foam’s inherent strength to weight ratio!

Consumer Goods

Molded foam is great at protecting anything from the smallest parts to large bulky items. It can be molded at incredibly tight tolerances for even the most delicate of parts. It offers exceptional cushioning properties and strength, yet is incredibly light. This saves on breakage and shipping costs. Molded foam can be shaped into just about any form, which allows for superior protection and labor-savings. One of the key benefits of molded foam is its “moldability”. This capitalizes on the feature of providing shock-absorbing packaging that is unique to your application. By shaping the material in specially-designed molds, we can incorporate a precision fit with proven packaging techniques to attain the highest level of protection. Savings are gained through less product damage from shipping and handling.

Molded foam serves many markets!

• Furniture; used as the furniture itself in some cases and packaging in others;

• Lawn/Garden; packaging for items like weed-trimmers and chippers (pictured here);

• Toys;

• Cookware;

• Lamps and Ceiling fans;

• Framed Pictures and Picture Frames;

• Small Arms and Ammunition;

• Wine and Beverages; single parcel shippers, etc.

Military

Molded foams are primarily used for three purposes in this market sector:

• Equipment/munitions preservation and intermediate protection.

• Packing and unitization.

• Transportation/logistics safety assurance.

There are many DOD and industrial approved policies, specifications, methods and techniques of packaging/package design utilizing molded foams as cushioning materials to provide adequate protection of military items at a minimum cost.

Medical & Pharmaceutical

Many temperature sensitive pharmaceutical and medical products use EPS because of its excellent thermal insulation properties. Strongly relied upon in the pharmaceutical distribution industry, EPS is ideal for long distance shipment of perishable items. EPS is highly resistant to heat/cold flow and the cellular structure of molded polystyrene is essentially impermeable to water.

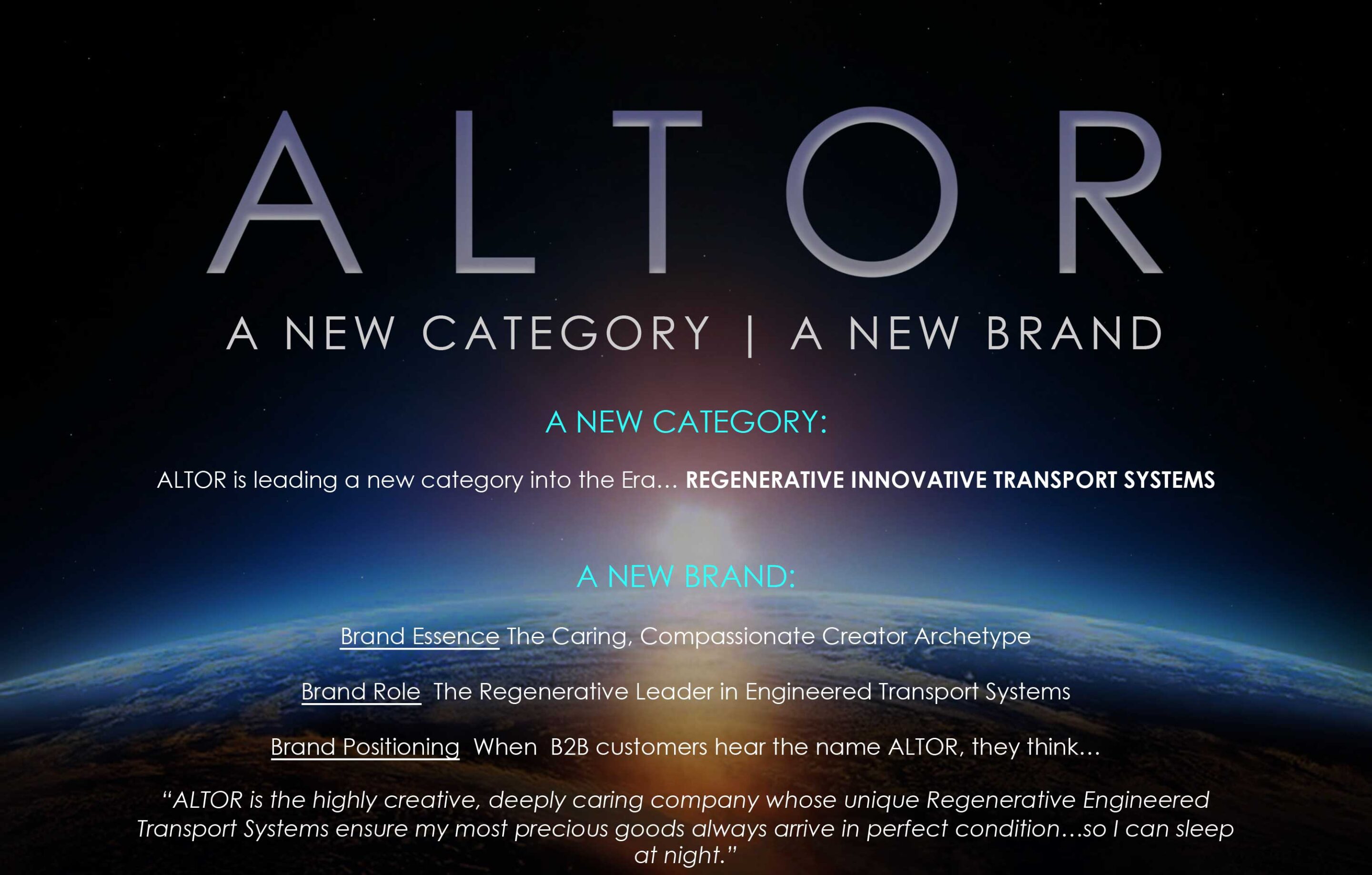

We look forward from hearing from you. Whether is is a stock item you need quickly or a custom project fulfilled, Altor Soliutions is your solution for everything PIC.

Contact Us

Phone Number

508 234-6323

888 740-3626