EPS Sustainability

Expanded polystyrene (EPS) is an engineered foam that helps solve a multitude of challenges, including protecting thousands upon thousands of products from spoilage and landfilling. Yet EPS is a misunderstood material. The fact is, it is often the most sustainable choice for a product.

There are multiple factors in the entire lifecycle of a product that affect our planet, and each one of those factors and how they collectively impact the environment should be considered. When that is accomplished we canthen make our best, most educated, most sustainablechoice for products such as packaging –and very often it is EPS.

Consider the following.

EPS is:

- Engineered foam and air. 98% air in fact. The foam pieces are made up of hollow spheres of material that are fused together-meaning even the largest parts are made with very little material.

- Recyclable. A number of municipalities collect#6foam for recycling, and that’s growing. In addition, there is a wide network of locations throughout the US and beyond that take in post-consumer material for recycling. Polyfoam is one of those locations and we take in thousands of pounds of material each year that is either recycled into new foam items or upcycled into other products. For more information on recycling locations click here. Also be sure to check out the video above.

- Lightweight. Because they are mostly air, foam parts are extremely lightweight. One major benefit of this is the low amount of energy required to transport. In fact, many automotive parts are formed EPS which helps keep vehicles’ weight and energy use down. For packaging EPS provides a lightweight vehicle for thermal and cushioning protection, which again requires less transportation energy. This also provides an ergonomic benefit in the lifting and handling of products.

- Reusable. Though lightweight, EPS is extremely strong and durable. That means that packaging and other products can often be reused multiple times, thereby extending the life of the product.

- Thermally Protective. With a high insulating value, products and people can be protected with a relatively small amount of material. Often used in the construction industry for products such as Insulating Concrete Forms (ICFs), EPS provides energy savings over traditional building methods, and the durability provides added protection from the force of weather such as hurricanes. In the pharmaceutical and food delivery industries, EPS coolers such as our Thermalok line provide a lightweight method to ensure critical items such as vaccines and medications arrive safely at the right temperature, preventing spoils.

- Shock Absorbing. Safety helmets are often made with EPS as a way to protect heads from impact. With its shock and stress absorbing quality, EPS is also used for automotive parts and for packaging to protect products from being damaged in movement. Fewer damages means less waste.

- FDA Approved. The FDA approved EPS for food contact years ago and it remains approved today.

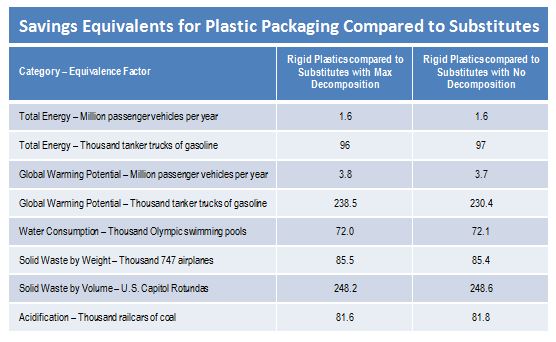

- Life Cycle Analysis Positive. Life Cycle Analysis (LCA), such as the research study conducted recently by Franklin Associates, consistently shows that plastic packaging compares favorably to other substitute materials such as paper.1There are wastes and impacts along the entire lifecycle of a products’ creation –not just at the end. That is what studies such as these examine –they look at ALL the effects. In the Franklin analysis, numerous environmental impact metrics were examined, and in each case the plastic packaging proved out better. See below for a link to the full study.

The following highlights some of the savings of plastic packaging versus substitutes:

Franklin Associates (2018,April). Life Cycle Impacts of Plastic Packaging Compared to Substitutes in the United States and Canada.

Available at:

https://plastics.americanchemistry.com/Reports-and-Publications/LCA-of-Plastic-Packaging-Compared-to-Substitutes.pdf

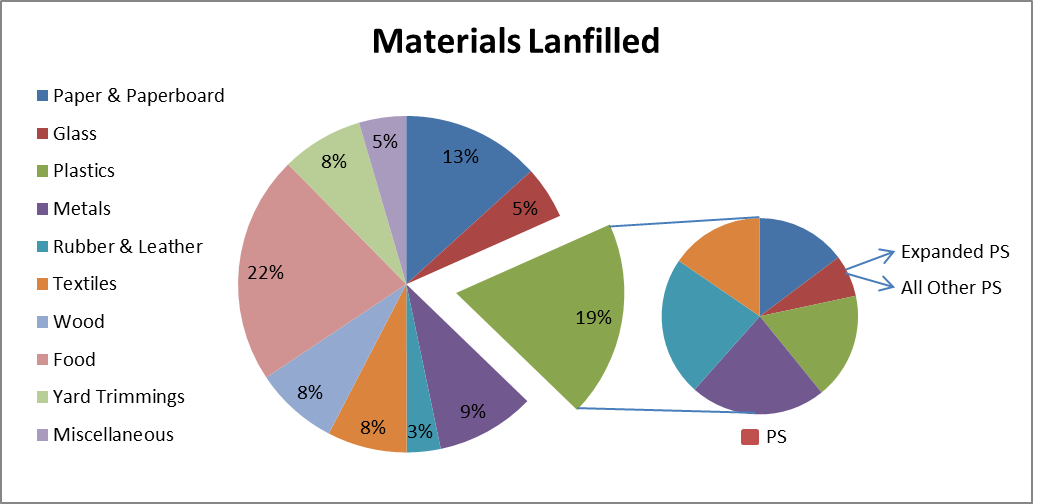

- A Minimal Piece. According to recent figures from the EPA, all polystyrene (including hard plastics such as plates, yogurt cups, margarine tubs, etc.) represents just 1.35% of the solid waste stream2. Expanded polystyrene (EPS) is an even smaller portion of that 1.35%, so its presence in the waste stream is very minimal.

- Effective. The bottom line is that no material is sustainable if it does not work. If a cooler fails to provide adequate insulation, or a corner pad adequate cushioning, the package fails and products are discarded. That is not environmentally sustainable. EPS products are proven, highly effective solutions to a vast array of challenges, including requirements for thermal and stress protective packaging, components, building products, and countless other applications. That effectiveness helps save energy and helps eliminate the potential disposal of countless numbers of damaged items.

Food waste actually takes up the largest amount of materials landfilled. And while food is biodegradable landfills are often anaerobic due to design or compaction, so most materials do not biodegrade as they normally would outside a landfill. Byproducts of landfills are also currently an issue. Methane gas, for example, has 86times more global warming potential than carbon dioxide over a twenty year period3. If not captured and destroyed or converted to energy, this has serious environmental consequences for our planet.

Environmental sustainability is a complex issue that needs to be carefully considered with facts and science.From that, the right material can be chosen and it will very possibly be EPS.

For more information on EPS and sustainability, check the EPS Industry Alliance website at: http://www.epspackaging.org/.

For more information on recycling EPS click here to see more on Altor Solutions and our Corporate Responsibility program.